We get asked this question almost every day, and the answer is straight up, you should only run 85W-140, API GL-6 rated conventional (non-synthetic) gear oil in a Currie axle assembly. You may hear about how synthetic gear oil provides reduced friction and wear; however, it may not be optimal for your setup – especially if you have a Ford 9-inch rearend. Hear us out.

The 9-Inch Gear Is Unique

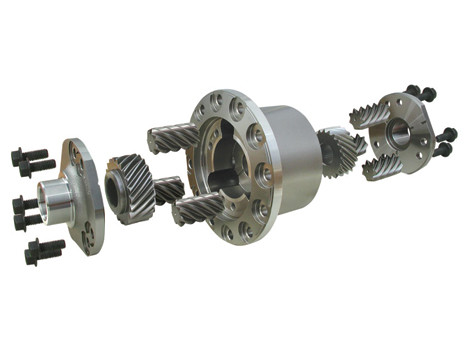

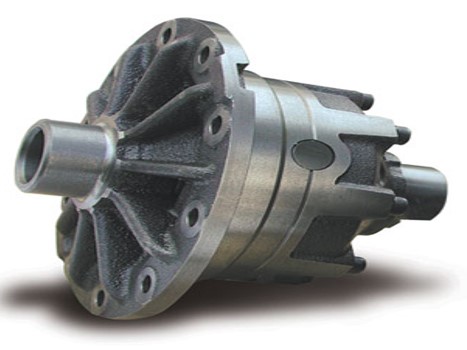

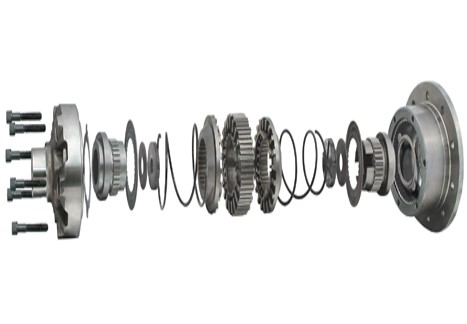

The design of the 9-inch features a high-offset distance that places the center-line of the pinion gear 2.25-inches below the center-line of the ring gear, which is substantial when compared to the 1.125 to 1.5-inch offsets of other gear sets (see image below). The high-offset distance increases the contact patch between the ring and pinion teeth by approximately 30-percent and is a crucial reason for the legendary strength of the 9-inch gears. However, strength comes at a price, as this high-offset distance creates increased sliding friction and heat across the gear tooth face. Because of this, not using high-shear oil such as Currie’s 85/140w can lead to scoring and certain gear death, especially during extreme scenarios such as off-roading and racing. The increased pressure capabilities and wear resistance found in Currie’s GL-6 rated gear oils are designed with all this in mind to ensure your rearend’s gears and bearings are adequately protected under the most severe conditions.

Pinion offset distance compared

API GL-5, Not Designed For A 9-Inch

Virtually all synthetic gear oils on the market today are only engineered to meet the API GL-5 specification, which Currie has found to be inadequate for the design of the 9-inch. The last 9-inch rearend rolled off the Ford assembly line in 1986, and it wasn't until 3-years later 1989 that the first synthetic gear oil, Mobile1 (GL-5 rated), hit the market. Just 9-years after the end of 9-inch production, in 1995, both the GL-6 standard and the test equipment were inactivated, making it unlikely that a synthetic oil manufacturer would go through the cost and effort to develop an oil to meet the obsolete GL-6 standard.

Conventional Oil Is Proven

Because many of today's commercially available synthetics are not engineered with the 9-inch's requirements in mind, Currie advises using only conventional 85W-140 non-synthetic GL-6 rated gear oil in all front and rearend applications. The viscous (thick) base stock of the 85W-140 oil (check out the videio)provides a cushion that helps protect the gears from shock loads and clings more effectively, pulling heat away from the tooth face and preventing localized heat build-up. The higher level of extreme pressure additives mandated by the GL-6 standard protects the gears from scoring and premature wear.

Racing and Severe-Duty

For high-performance applications such as drag cars, desert trucks, circle track, or anywhere a 10-inch gear makes sense, we recommend stepping up to our 250W conventional GL-6 gear oil. The higher viscosity provides additional protection from high shock loads, while increased levels of extreme pressure additives help further protect the gears against scoring loads.

Finally, conventional GL-6 rated gear oil is proven to work, which is why it's a requirement of our product warranty terms for all Currie axle assemblies. With 50-years of experience building and servicing rearends for every imaginable application, we are confident that our gear oil is an excellent choice for your next build.