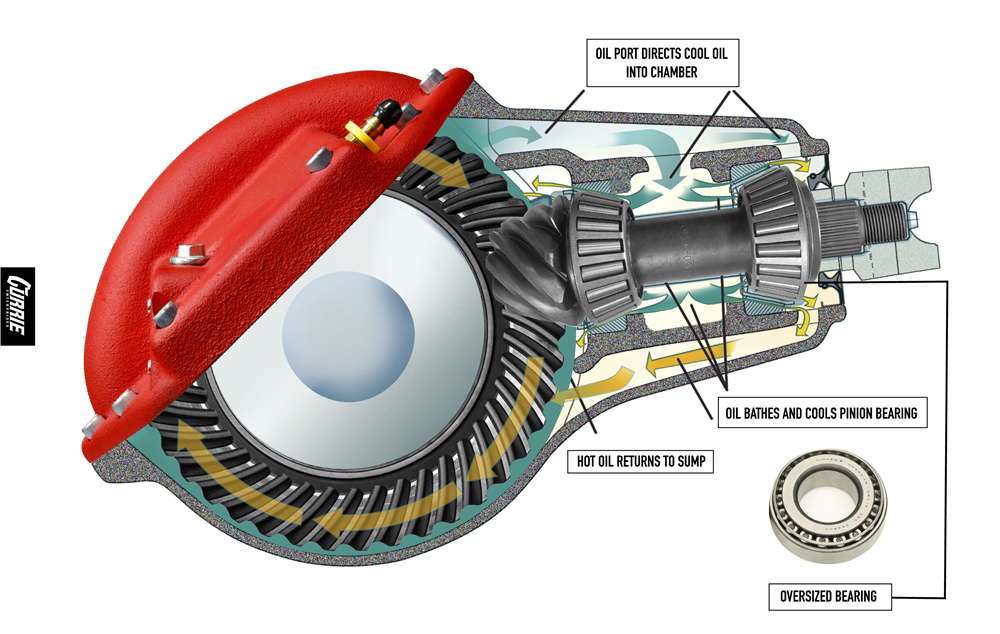

For more than two decades, Currie Enterprises has offered strong, durable high-pinion axles for a variety of applications. Besides overall strength, a critical element in long term reliability is pinion bearing lubrication. On high-pinion setups, the location of the pinion gear and yoke are elevated for improved ground clearance, so the oiling system design must overcome gravity to achieve proper lubrication.

A standard low-pinion axle places the pinion bearings below the static gear oil level, where they are by default covered in a bath of gear oil. Conversely, a high-pinion axle puts the pinion bearings above the static gear oil level, so the engineers at Currie implemented a unique design to assure that a sufficient flow of gear oil is present to lubricate and cool the bearings.

By integrating a high-volume flow-through oiling system (pictured below) that incorporates a large port above the pinion gear, Currie’s high-pinion axles deliver a constant flow of gear oil into a chamber that supplies the pinion bearings with fresh gear oil at all times. In operation, gear oil is lifted and pumped into the port by the rotation of the ring gear, as the port fills the chamber, gear oil flows through the bearings and back to ring gear, ensuring adequate lubrication and cooling.

Currie High-Volume Flow-Through Oiling System

The oiling system is so efficient that it supports pinion angles up to 15 degrees to be run in rearend applications and still maintain proper pinion bearing lubrication.